SIO the other newsletter – No. 157: FilmDoctor® iStress module – recap

An informed approach to optimize longevity and reliability of layered films

By Troy vom Braucke and Nick Bierwisch

In mechanical engineering and materials science, optimizing material systems for enhanced performance and longevity often involves strategies such as:

– Surface strengthening (e.g., nitriding)

– Improved material combinations

– Use of novel coating materials

– Changing the structure and deposition process.

However, the residual stresses, resulting from manufacturing or processing steps, mostly define the performance and limit the lifetime of nanostructured materials, thin films, coatings, and MEMS devices.

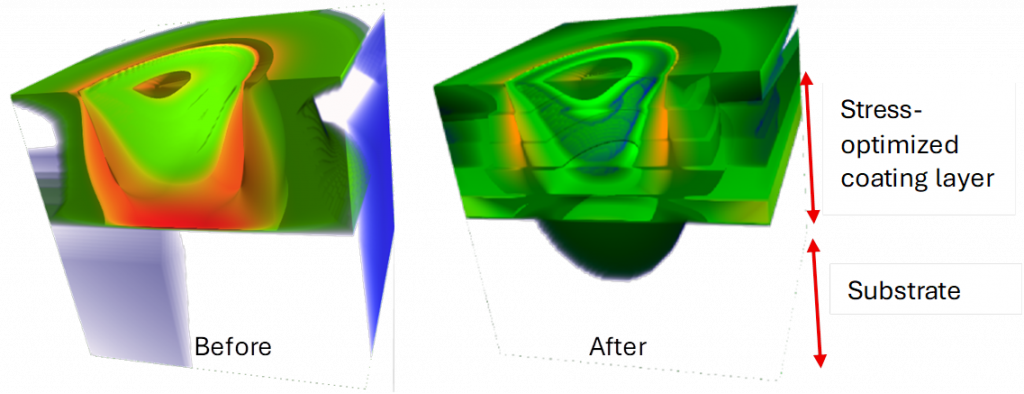

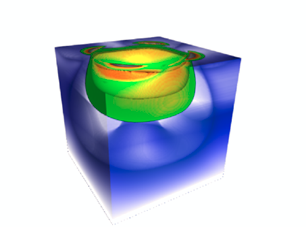

An EU-funded consortium project sought to leverage inherent residual stresses in coating-substrate systems rather than mitigating them. The project’s core insight was to engineer tailored residual stress profiles for specific contact conditions, thereby reducing peak stresses and improving load-bearing capacity.

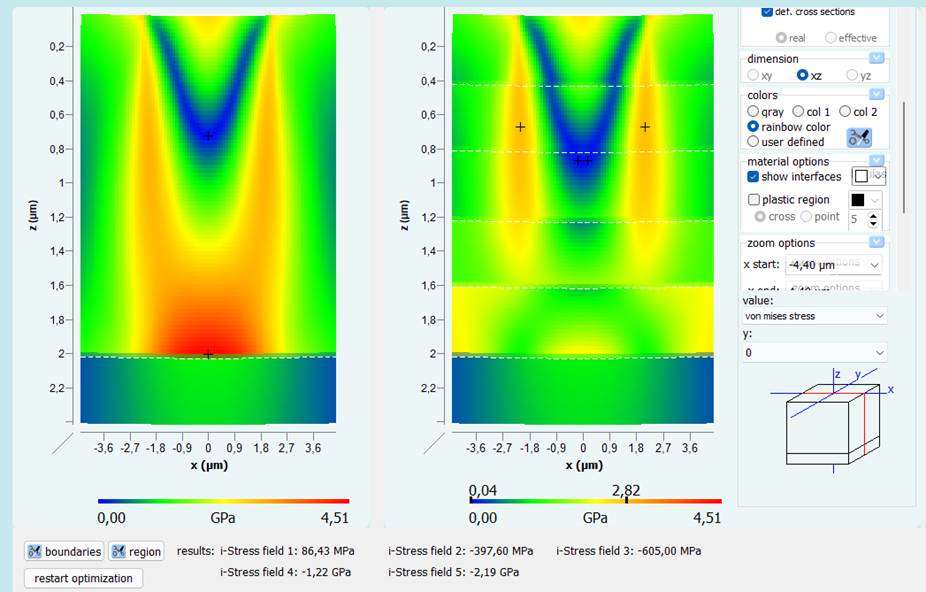

As a key outcome, SiOmec developed the iStress module within FilmDoctor®, which computes optimal stress distributions using analytical models for given operational scenarios. Project partners subsequently refined their manufacturing process techniques to achieve these profiles.

The iStress Module Workflow:

- Select the target layer for optimization in the multilayer system.

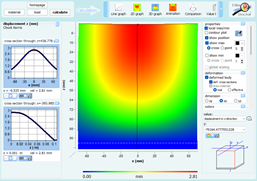

- FilmDoctor® iStress evaluates the complete stress-strain-field of the original state.

- User decides how many discrete sublayers are desired in the selected layer.

- The optimal residual stress values per sublayer are calculated to create a stress distribution with lower stress maxima.

In a representative example shown in Figure 2, the maximum von Mises stress decreased from 4.51 GPa (original) to 2.82 GPa (optimized), nearly halving the von Mises stress maxima without material changes.

An applied example can be found in the tutorial video in part 2 of ‘Implants of a Lifetime’

For further technical details of the EU project, including measurement protocols for sub-micron residual stress analysis and integration with our simulation tools see: https://cordis.europa.eu/project/id/604646/de

[1] Example geology from https://geology.utah.gov/map-pub/survey-notes/horizontal-drilling-utah/

[2] N. Schwarzer, “Fluid Universe: The Way of Structured Water – mathematical formulation”, Jenny Stanford Publishing, forthcoming release in 2026).

If you have any questions concerning the theory, please contact Norbert Schwarzer directly via email: n.schwarzer@siomec.de

If you have any questions concerning the software and animation, please contact Nick Bierwisch: n.bierwisch@siomec.de

For all other concerns (software, offers, development, investor requests) address Peggy Heuer-Schwarzer: p.heuer@siomec.de or Troy vom Braucke: troy@gpplasma.com

SIO the other newsletter – No. 156: Stress Testing a Chuck Norris Meme with FilmDoctor®

Stress Testing a Chuck Norris Meme with FilmDoctor®

By Troy vom Braucke

It has been said that when Chuck Norris does a push up, he isn’t lifting himself up, he’s pushing the Earth down!

This meme has been kicking around for years and captures the over-the-top toughness of the martial arts legend. Let’s put it to the test with FilmDoctor®, does Chuck actually move the Earth?

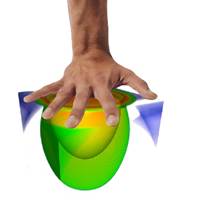

Using a mass of 77kg for when he was in his prime, and a typical push up height of 0.3m gives approximately 226 Joules of potential energy, or 113 Joules per hand for a two-hand push up. So clearly for Chuck, we will use 226 Joules for a one-handed push up.

Taking a contact area for an adult male palm of 10cm x 10cm gives a circular radius of 5.64cm, but with a relatively flat contact radius ‘a’ when in contact with the ground.

Running the contact analysis in FilmDoctor®, it seems Chuck does push the earth down, but only the part just below his hand. Perhaps you might like to try a Karate chop to a wooden board?

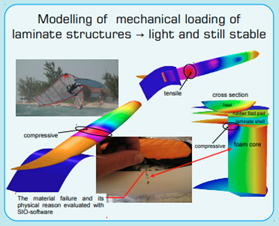

All fun aside, understanding the contactconditions of a hand or foot on the reliability of in-homogeneous layered materials can be critical, like for sporting equipment under extreme scenarios such as our windsurfer example here:

http://siomec.com/wp-content/uploads/2023/06/2007-006.pdf

Meme Data: We used a compressible loamy soil (E= 15MPa, v= 0.15) 10cm deep, above Sandstone rock (E=84GPa, v = 0.13).

If you have any questions concerning the theory, please contact Norbert Schwarzer directly via email: n.schwarzer@siomec.de

If you have any questions concerning the software and animation, please contact Nick Bierwisch: n.bierwisch@siomec.de

For all other concerns (software, offers, development, investor requests) address Peggy Heuer-Schwarzer: p.heuer@siomec.de or Troy vom Braucke: troy@gpplasma.com

SIO the other newsletter – No. 155: Efficient Oil Extraction with FilmDoctor®

Efficient Oil Extraction with FilmDoctor® – Safer, Smarter, Subsidence-Free

By Troy vom Braucke

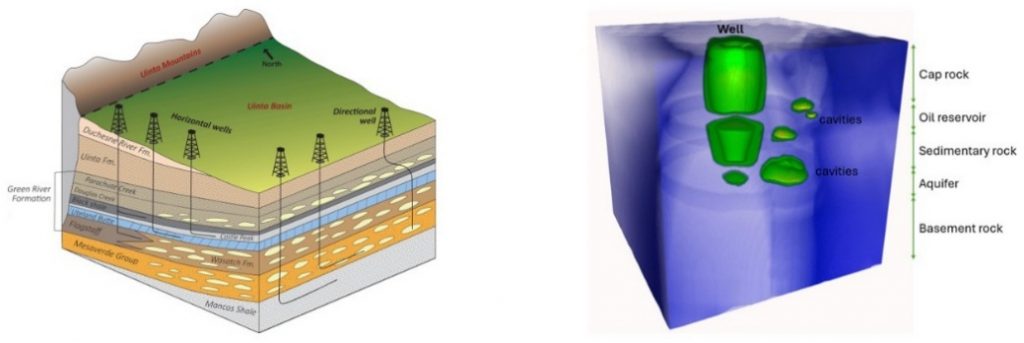

FilmDoctor® uses analytical physics to simulate digital twins of stress and strain fields in multi-layered oil reservoirs, cutting subsidence risk (by up to 90% in our hypothetical example below)—faster and more precise than FEA, and using real site data or literature values for preliminary analysis.

Traditional extraction softens the oil-bearing sandstone, leading to a risk of casing collapse, with wells typically limited to 40-50% of the oil being feasibly extracted.

We simulated traditional extraction methods compared to new state-of-the-art technology from RASA® to understand risks as oil is depleted due to the impact of lost circulation zones and costly repairs in the millions, while showing potential for real-time optimization of oil fields.

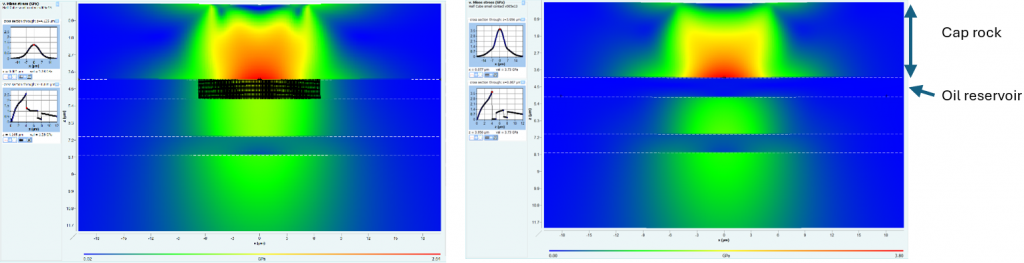

Using traditional extraction methods, the porous oil-bearing layer suffers from pore compaction as the oil is drained, leading in our example to increased von Mises stress of 1.3 GPa exceeding the yield strength (see Figure 2a). FilmDoctor® flags these changes preventively to help avert casing collapse.

In contrast, we explored the flexibility of RASA®’sadvanced tech, evaluating a process tweak with the simulation to show the result of significantly reducing viscosity in layer 2.

Max von Mises stress in layer 2 below 200 MPa and within the yield strength of the substrate (see Figure 2b). The process effectively annealing out the stress, converting layer 2 close its original stress-free “virgin” state, an impact as dramatic as the following image for oil-field economics:

FilmDoctor® bridges geological-scale oil reservoirs to nanoscale applications.

Building on this layered approach to minimize stress, a similar approach—echoing viscosity cuts in reservoirs— applies in aluminum-graphene batteries to allow for low-resistance domains of ion flow, enabling rapid charging with minimal heat and wear to extend cycles.

These layered solutions exploit core physics [2] to boost performance.

Ready to create a digital twin of your Well?

Contact us for a FilmDoctor® Demo—Transform your site data into wins.

If you have any questions concerning the theory, please contact Norbert Schwarzer directly via email: n.schwarzer@siomec.de

If you have any questions concerning the software and animation, please contact Nick Bierwisch: n.bierwisch@siomec.de

For all other concerns (software, offers, development, investor requests) address Peggy Heuer-Schwarzer: p.heuer@siomec.de or Troy vom Braucke: troy@gpplasma.com

References

[1] Example geology from https://geology.utah.gov/map-pub/survey-notes/horizontal-drilling-utah/

[2] N. Schwarzer, “Fluid Universe: The Way of Structured Water – mathematical formulation”, Jenny Stanford Publishing, forthcoming release in 2026).

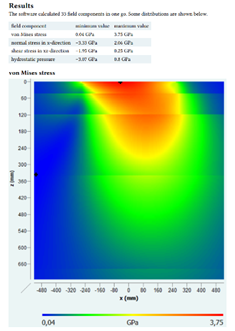

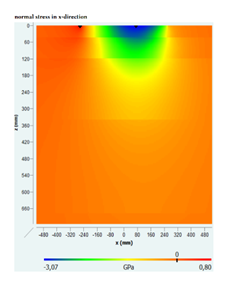

SIO the other newsletter – No. 154: Update: Simplified Reporting with FilmDoctor®

By Troy vom Braucke and Nick Bierwisch

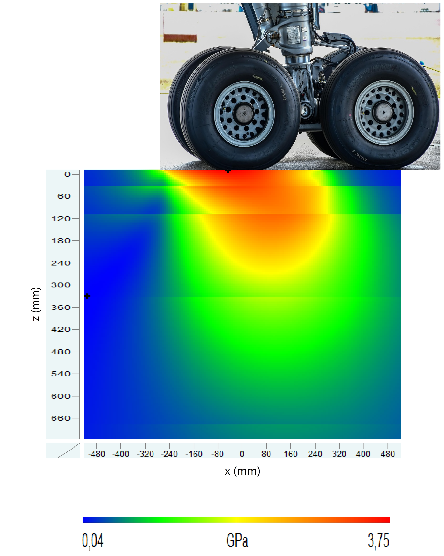

In a recent newsletter we discussed the application of a jet landing on a runway to understand the stresses in the landing zone for hard, soft, and taxiing scenarios.

However, sharing your FilmDoctor analysis to colleagues meant manually exporting data sections, images, or entire project files—time-consuming and fragmented, with no one-click option for a complete report for each module used.

We’ve integrated Typst [1] – a fast, open-source LaTeX alternative – to generate professional, presentation-ready PDF reports instantly. One button exports all data, images, and analysis summaries for select modules, making it effortless to extract insights, share with teams and project partners, and archive.

See attached example reports for OPfC® and FilmDoctor® modules, based on our jet runway landing scenario—complete with input data and stress field visuals.

We’re rolling this out to more modules soon.

Contact us today for your free software update (while available in your update period) or to check compatibility with older versions. Let’s streamline your workflow!

If you have any questions concerning the theory, please contact Norbert Schwarzer directly via email: n.schwarzer@siomec.de

If you have any questions concerning the software and animation, please contact Nick Bierwisch: n.bierwisch@siomec.de

For all other concerns (software, offers, development, investor requests) address Peggy Heuer-Schwarzer: p.heuer@siomec.de or Troy vom Braucke: troy@gpplasma.com

References

[1] Typst (http://www.typst.app) an open source Latex alternative which offers us new ways to create reports, summaries and so on. It was developed in Berlin, Germany and is written in Rust which makes it extremely fast and more flexible than creating document with Latex. Our software collects the needed data, creates the images and prepares the document. In the following step that document is compiled with Typst (mostly in under 1 second) and the final PDF document is created.