Graphene and other 2D materials are important for many technology applications from batteries to computer chips and more.

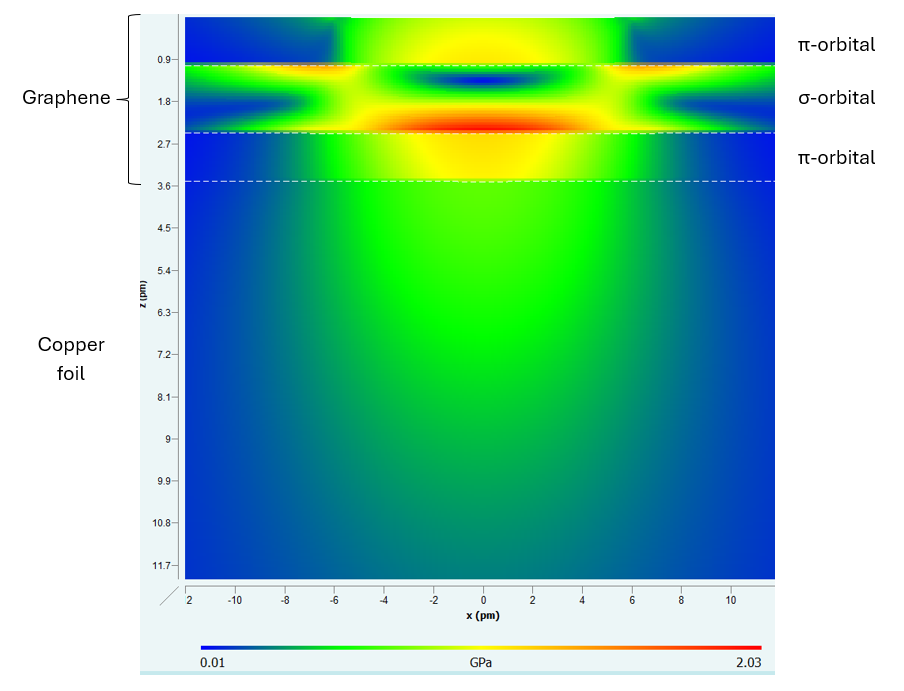

Graphene was one of the first materials used to validate FilmDoctor® over 25 years ago at the University of Chemnitz theoretical physics department.

Validation was by comparison to a non-truncated Molecular Dynamics (MD) orbital model and to experimental results. The result … perfect agreement with both! Only the MD model took one month of supercomputer time and FilmDoctor® need only a few seconds on a laptop.

These massive time savings have a huge impact on the return on investment from labor savings, consumables, and increased machine uptime. Allowing your company to get ahead of the market while reducing capital expenditure. A tier one automotive supplier accelerated their thin film product development from 3 years down to 3 months!

Classical Molecular Dynamics (MD) and Finite Element (FE) simulation methods are used by scientists and engineers to optimize material designs for different applications or to understand the formation of these materials in manufacturing. But these techniques contain approximations and have limitations in simulating large numbers of atoms and are not invertible for reverse optimization.

First principles analytical physics methods [1] provide the ability to understand how small-scale effects can lead to large scale failure problems. Making it possible to speed up your troubleshooting optimization cycle.

Due to hyper efficient mathematical physics that is scale invariant (from small to large scale analysis) and invertible (reverse optimizable), the analytical approach takes a few minutes to set up the design problem. The unprecedented simulation speed means it requires just a few seconds to calculate the material performance under desired contact loading conditions.

The use of experimental measurement data input to the simulation allows a layer structure refinement to ensure agreement with experiment and competing methods such as FE and MD. However, without the limitations of those latter methods, in seconds you can run different thought experiments on your laptop if experimental techniques are not available.

Graphene and Graphene-Like Materials

MD approaches use effective potentials with corrections and therefore, not a fundamental 1st principles approach. They are not accurate if going for more than 1000 atoms as they still use tight binding approximations. Today’s workstations may now do the MD calculations within a week, but FD is still just a few seconds on a 1.6GHz, 4-core laptop.

[1] N. Schwarzer, “Scale invariant mechanical surface optimization applying analytical time dependent contact mechanics for layered structures”, Chapter 22 in “Applied Nanoindentation in Advanced Materials”, Atul Tiwari (Editor), Sridhar Natarajan (Co-Editor), ISBN: 978-1-119-08449-5, 2017, www.wiley.com/WileyCDA/WileyTitle/productCd-1119084490.html