We not only organize measurements on leading technical instruments (e.g. UNHT, MHT, NST, MST, UNAT mit LFU, NanoTest Vantage, Nano Indenter G200, Nanoindenter XP, UMIS 2000 etc.) which are most appropriate to your product and application, but also offer accurate dimensioning and physical analysis of all mechanical contact measurements including a final report which is adapted directly to your product.

Our specialty are specifically designed experiments and their physical analysis way better than any standard:

- profiling: profiles of hardness, elastic modulus, and yield strength

- multi-axial indentations: tensile strength, adhesion, fracture strength, instrinsic/thermal/residual stresses

- micro-wear tests: determination of initial failure

- 3D indentation: 3D surface topography considered

- 3D scratch test: 3D surface topography considered

Material Characterization via Nanoindentation – Standard Measurements

Demands on sample quality and size

| Maximum sample size: | approx. 70 x 50 x 30 mm³ (length, width, height) |

| Optimum sample size: | approx. 10 x 10 x 3 mm³ |

| Minimum sample size: | approx. 1 x 1 x 0.3 mm³ |

New: By using special adapters it now is possible to measure also small non-planar samples (e. g. samples with strongly curved surfaces). That is how twist drills with only 1 mm radius can be measured. Please contact us if you intend to measure such samples.

Other sizes require consultation.

Sample surface and bottom have to be flat and parallel (a curvature of the upper side is acceptable if the radius is not too small).

Surface roughness should be as low as possible.

As a rule of thumb:

Ra<5 nm or Ra<5% of the penetration depth or Ra<1% of the film thickness in areas of at least 10 x 10 µm².

Material characterization by surface tests of the next generation – Non-Standard Measurements

With additional lateral loads more material parameters and structural information can be determined (e.g. fracture limits and intrinsic stresses).

All measurements and analyses can be performed time and temperature resolved.

Other indenter geometries and tests

- Nanoscratch tests (allows determination of failure mechanisms under realistic mixed loading conditions, much closer to the later application)

- Complete field animation of any contact (indenter-, scratch- or groove-) tests

- Elastic spherical indentation inclusive SIO-Analysis

- Special lateral force indentation on request, but similar to nanoscratch test

- Determination of local intrinsic stresses via Nanoindenter, also possible as complete surface mapping

- Determination of Poisson’s ratio (no estimation as in classical O&P method)

- Complete correction of pile-up and sink-in effects

- Determination of local residual stresses via defect approach [3], also possible as complete surface mapping

- Determination of local anisotropy via Nanoindenter, also possible as complete surface mapping

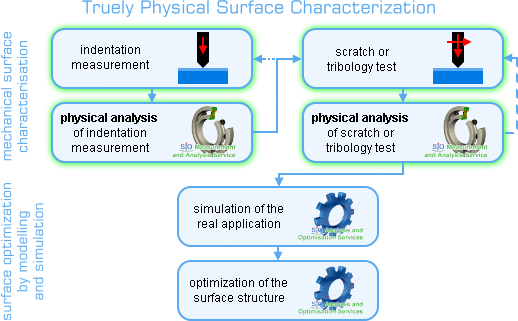

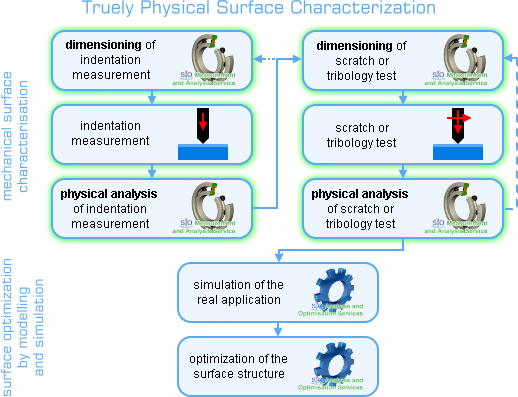

As there is a great variety of measurement possibilities, SIO suggest a proper pre-dimensioning of the measurement itself. Thereby we design an optimum measurement process perfectly adjusted to the sample in question, its later application and service life span. This includes suggesting the best measurement devoice, indenter types and sizes, loads (normal, mixed, tilted, twisted …), analyzing methods, expected errors etc.

Mechanical Characterization

The most important aim of mechanical characterization is the evaluation of generic material properties, which are independent of measurement conditions (like material structure of the sample, maximum indentation depth, initial and final load, velocity etc.). Hence, it is necessary to take all these measurement conditions into account to evaluate such measurement properly. That is why we have extended the classic Oliver&Pharr method for such conditions. This Oliver&Pharr method extended for layered materials (Oliver&Pharr for Coatings) enables you to calculate – among others – the following generic material properties:

- real Young’s modulus of each layer or the substrate (elastic modulus)

- yield strength of each layer or the substrate

- Poisson’s ratio of each layer or the substrate

- intrinsic, thermal, or residual stresses of each layer or the substrate

- tensile strength

- adhesive strength

- critical stresses of all fracture modes (mode I crack, mode II crack, and mode III crack)

- layer thicknesses

Only these generic physical material properties can be reused in nearly any other surface structure (e.g. for surface optimization by means of modelling and simulation) without being obliged to repeat the characterization.

Of course, we can determine the correct hardness, too. But be aware: Hardness is neither a physical nor a generic material property!

Mail: info@siomec.de