Physicalization of existing measurement techniques

With the help of our new and improved physical models you can get more out of your conducted tests and thus, gain qualitative and quantitative advantage from conventional measurement techniques.

- Organization of measurements that are appropriate for your product

- Physical analysis of experimental data by using new models

(e.g. “Pharr’s effective indenter” for layered materials and curved surfaces) - Evaluation of forces (e.g. F0) which are critical for the first failure of a material.

- Evaluation of the complete stress field in the moment of failure

We obtain the critical stress that is responsible for the failure in the material.

Test Instrument Acquisition

There are many mechanical surface measurement instruments with very different advantages and disadvantages on the market. Their evaluation according to your needs is a quite complex task which requires thorough knowledge in surface mechanics.

Consulting about Measurement Instrument Acquisition

The choice of a surface tester is very important, because the results of the physical evaluation can only be as good as the measurement data obtained from the measurement instrument. The answer to the question “Which is the most appropriate measurement equipment for you?” depends on many aspects, e.g.:

- Which material (classes) are used and which typical properties do they possess?

- How complex are the surface structures of your products?

- To what purposes should the surface tester be used?

- What are the intended applications of your products?

- Which information does a measurement instrument provide in addition to the mere measurement data?

- What quality are the measurement data of?

- Which measurement methods are supported?

As each measurement instrument has got its advantages and disadvantages, it is more or less appropriate for certain objectives. Hence, it must be determined accurately which one of the various surface test equipments available on the market meets your needs best according to the criteria mentioned above and a lot more.

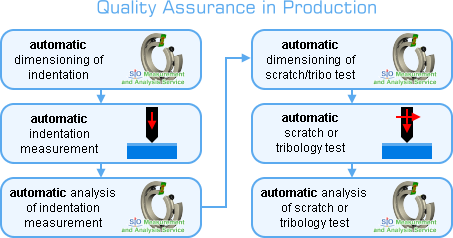

Quality Assurance

Using certain surface measurement instruments (e.g. nanoindenter) in production for quality check has some significant advantages compared to other methods resulting in an increasing reliability of quality checks and therefore, in a reduction of the failure probability of your products. Since it is possible to fully automate not only the contact measurement but also their physical analysis, such contact measurements can be integrated in almost any production process. Thereby, a objective quality check can be ensured.

If you use measurement instruments with our subsequent physical evaluation not only in production for quality check purposes, but also in research & development to design and optimize surface structures, you will be able to support and establish, respectively a holistic quality management specifically.

Ask us for specific consulting

Mail: info@siomec.de